BPX hits it out of the park with 3 Bossier Parish CULs

As most folks know, HA operators have been drilling long CULs. And today, per a SONRIS update, BPX recently came online with some eye-popping stats on three humongous CULs off a single pad in section 30 16N 11W.

The three alt wells are labeled: HA RA SUB; HORTON 30-19-18C. And the attention grabber is the volume. The 001-ALT completed at:

| 06/03/2025 | 10 | 26168 | 10980 | COMPLETED 4/9/25; GAS; 64524 MCFD; 45/64 CHOKE; 7145# CP; PERFS 11440-26097' |

Wow. That's a lot of MCFD. Quite huge. Large choke, too. So it sounds to me like there's gonna be a lot of happy feet dancing in Bossier Parish in the coming months. Congrats folks. Thank you BPX.

Replies to This Discussion

-

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 7:24

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 7:24 -

Congratulations, Jesse. Hopefully you'll not mind my adding a little context. This three section lateral is 14,508'. You can think of it as three individual wells with average lateral lengths of 4914'. That would be 21,508 mcf/d average for each non-CUL well which would be a very good average per well. The three unit lateral wells are a way for operators to save money but aren't that different from horizontal wells with the same or similar completion designs that produce from a single unit/section. Instead of drilling three well, they drill one - saves money. Instead of three surface locations, one - saves money. Fracing two or more wells at the same time - saves money. It is less the lateral length and more the completion design that is responsible for the Initial Production (IP) rate. And a more open choke setting is required for the well to "clean up" - flow back the water and sand that was used in the frac. The completion designs today are a far cry from eight years ago and far, far different from twelve years ago. Frac stages are shorter - ~100' compared to ~300". The two Horton wells have stages of ~150 (14,742/98 stages) Perf clusters are vastly different but there is little publicly availabe data on how different. The proppant loads per linear foot of perforated lateral are ~3600 #. Early wells averaged anywhere from ~1200# to ~2000#. Amazing evolution in well and completion designs but unfortunately it has taken fifteen years or so to get to this point. The rush to drill and HBP (hold by production) the millions of acres of original leases meant the same well and completion designs were used over and over with little to no effort to make improvements. The well designs now are much more productive.

-

Permalink Reply by Jesse Joyner on June 5, 2025 at 8:02

-

Thank you, Skip. Please add your expert context anytime. I like learning stuff I don't know, and I've truly learned so much from GHS and your heroic efforts over the years.

I think these 3 CULs, two initially permitted on SONRIS as a twosome, then a bit later, the third permitted a bit later, where held back on the land-rush drilling by the first operators before BPX acquired the rights. This may've been done due to the high IP stats on an early vert in section 30 from years ago. In other words, I'm speculating that the other operators (and later BPX) initially delayed the drilling of this location since the rock was so darn good.

Now, of course, I could be wrong. It could've been numerous other reasons, e.g., leasing, pipeline, development $, etc. Unsure. But as it turned out, my family looks to be benefiting from the delay per the advancement in completion technology. Lucky us.

Plus, BPX, even though their new CEO had cut back to just one rig (due to low NG prices) in Bossier P. over these last couple of years -- that might be changing. Unsure. But now they seem to be putting the pedal to the floor. I could be wrong. Yet from my family's other mineral-right locations and from scuttlebutt, it smells like there's a bit of aggression going on.

So, thank you, sir. My family truly appreciates all the info sharing you've done over these last 16 years or so. You da man. LSU has some great alum. My alma mater.

-

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 9:43

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 9:43 -

You're welcome, Jesse. Keep learning. It pays to know as much as you can about your mineral interests.

-

Permalink Reply by w.r. frank on June 5, 2025 at 10:41

Permalink Reply by w.r. frank on June 5, 2025 at 10:41 -

Very good Skip. The really good news is, evidently, it is a Bossier in 16N!!! You are correct that most wells come in at 20,000 Mcfd to 25,000 Mcfd/unit. They are very quickly dialed back to about 12,000 Mcfd/unit and pressure draw down is very closely monitored with choke size to avoid production decline. §§§30&19&18 are right on the N/S line with 12W. So16N is really. really encouraging if it is Bossier.

-

Permalink Reply by Les on June 5, 2025 at 11:15

Permalink Reply by Les on June 5, 2025 at 11:15 -

Very interesting discussion...way above my level of knowledge on the technical side of the industry but I'm always willing to learn. Likewise, I haven't mastered the use of SONRIS yet. I have some mineral interests in Bossier Parish, Section 12, Township 16, Range 12 West, but I can't seem to tell if my interests are anywhere near these new BPX wells you are referencing. Any help would be appreciated.

-

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 11:23

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 11:23 -

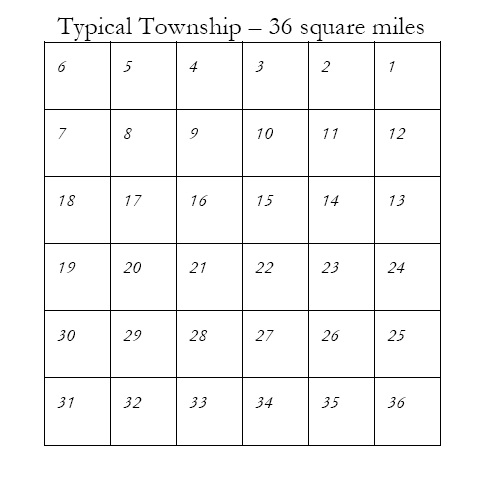

Les, use the link below and print out a township grid that shows the relationship of sections. Then use this link and save the SONRIS search page to your computer. When you search leave the section box blank and just enter the Township and Range information. The you will see all sections and wells in that township. From there just ask questions. Good luck.

https://sonlite.dnr.state.la.us/sundown/cart_prod/cart_con_sectwnrng1

https://www.google.com/search?client=firefox-b-1-d&q=township+g...

-

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 12:24

Permalink Reply by Skip Peel - Mineral Consultant on June 5, 2025 at 12:24 -

You're welcome, Les.

-

Permalink Reply by Skip Peel - Mineral Consultant on June 6, 2025 at 1:56

Permalink Reply by Skip Peel - Mineral Consultant on June 6, 2025 at 1:56 -

Les, I should have added something about how SONRIS organizes well data. The wells are organized by the section where the well pad, drilling location is located. However these are horizontal wells and operators prefer to drill from pads that are adjacent to the section or sections that a well will produce. Since the wells are drilled on north/south axis, this is what you should keep in mind. A well in Section 6 may be drilled north from Section 7 or south from Section 31 in the township immediately to the north. With long lateral wells, a drill site in 5 might drill south to produce from Sections 8, 17 & 20. It is rare but occasionally a section or sections may be drilled from a site that is in a section to the east or west. For example, a drill site in the southeast corner of 7 could drill the vertical portion of the wellbore eastward into Section 8 and then south. SONRIS was created and designed in the age of vertical wells when there were very few if any horizontal wells and few directional wells. That was when the state created the "Deep or Horizontal" severance tax incentive that has cost the state billions of dollars in lost revenue and supercharged the profits of horizontal drillers.

-

Permalink Reply by Skip Peel - Mineral Consultant on June 9, 2025 at 8:40

Permalink Reply by Skip Peel - Mineral Consultant on June 9, 2025 at 8:40 -

WR, the Horton 30-19-18 HC wells appear to be Haynesville completions as opposed to Bossier Shale. All the H wells in Section 30, drilling north have TVDs of 10,904 to 11,041. That 137' variance in landing depth does not look like Bossier to me. In that locale I would expect something on the order of a 500' variance in TVD between a Haynesville Shale well and a Bossier Shale well.

-

Permalink Reply by Ryan Howrish on June 11, 2025 at 3:04

Permalink Reply by Ryan Howrish on June 11, 2025 at 3:04 -

Generally, I agree with this. The Bossier target thins as you move North in the basin. There has been very little Bossier activity farther North than TWP 13N/14N, and even that activity is low in comparison to T9N, T10N, and T11N. The Bossier fairway is expanding to the North, and operators will continue to test it. In the right conditions, it could be economic for operators to develop the Bossier, even if the productivity is less than it is farther South in the basin.

-

Permalink Reply by Ryan Howrish on June 11, 2025 at 3:13

Permalink Reply by Ryan Howrish on June 11, 2025 at 3:13 -

I'll add a little more context to this 24-hour test report. Skip is correct that frac designs and flowback strategies are significantly different today than they were 7 or 8 years ago, and that contributes substantially to the early-time productivity of newer wells.

You are correct; a test rate of 64 MMcf/d is a significant amount of gas, even from a 14,500-foot lateral. For comparison, at GEP, we tested a well at 62.7 MMcf/d from a 9462ft lateral. On a normalized basis, the BPX well tested at 4,447 mcf/d/1,000 ft of lateral at 7,145 psi. The GEP well I was a part of tested at 6,631 mcf/d/1000 ft at 8,024 psi. The normalized rate was almost 50% higher, and the flowing pressure was higher. This isn't surprising because as you move North, the Haynesville gets shallower and the reservoir pressure is lower. Generally, the lower the pressure, the higher the decline, assuming the production strategy is the same. With this said, the normalized test rate is much higher than the average well. The chart below shows the distribution of normalized test rates by first production year. The labels beside each box indicate the median value for each year.

Not all operators have the same production strategy. Some will be more aggressive in lowering the wellhead pressure by opening the choke to maximize early-time production, while others will be more conservative in their approach. I'm in the camp of being more aggressive early, as I haven't seen results that indicate significant formation damage caused by reducing the flowing pressure too quickly.

When I worked in the play, we conducted extensive testing on frac design by adjusting key parameters, including proppant loading, water loading, stage, and perf cluster spacing. We tested fluid loading up to 130 bbl/ft, proppant loading up to 4,000 lb/ft, and stage spacing as tight as 30-40 ft. The amount of water used in the frac plays a significant role in the cost of the frac. Even pumping at 70-80 bbl/min, where possible, it takes a considerable amount of time to pump 80+ bbl/ft in each stage. We found that the water loading was statistically more significant to well productivity than proppant loading, and we tended to pump higher fluid loadings with slightly lower proppant loading. Stage spacing is also an important factor in the cost, as it requires considerable time to set plugs for each stage, necessitating a balance between time, price, and benefit.

The earliest wells in the play had very conservative frac designs relative to today. Many of them had fluid loading in the 15-30 bbl/ft range, proppant loading in the 800-1200 lb/ft range, and stage spacing wider than 300 ft. After many design iterations, those parameters were deemed not to be optimized. The table below shows the average fluid and proppant loading by first production year.

Support GoHaynesvilleShale.com

Top Content

Groups

-

WESTERN HAYNESVILLE

17 members

-

Natchitoches Parish

405 members

-

Bienville Parish, LA

249 members

-

SMACKOVER LITHIUM GROUP …

10 members

-

SONRIS Help Center

255 members

-

Sabine Parish, LA

456 members

-

Evangeline Parish

17 members

-

SMACKOVER LITHIUM GROUP …

8 members

-

North LA Cotton Valley C…

67 members

-

Webster Parish

301 members

Blog Posts

Tuscaloosa Trend Sits On Top Of Poorest Neighbourhood For Decades - Yet No Royalties Ever Paid To The Community -- Why??

In researching the decades-old Tuscaloosa Trend and the immense wealth it has generated for many, I find it deeply troubling that this resource-rich formation runs directly beneath one of the poorest communities in North Baton Rouge—near…

ContinuePosted by Char on May 29, 2025 at 14:42 — 4 Comments

Not a member? Get our email.

© 2026 Created by Keith Mauck (Site Publisher).

Powered by

![]()

| h2 | h2 | h2 |

|---|---|---|

AboutAs exciting as this is, we know that we have a responsibility to do this thing correctly. After all, we want the farm to remain a place where the family can gather for another 80 years and beyond. This site was born out of these desires. Before we started this site, googling "shale' brought up little information. Certainly nothing that was useful as we negotiated a lease. Read More |

Links |

Copyright © 2017 GoHaynesvilleShale.com